We are excited to share new progress from our biomaterials surface engineering studies. Using a controlled ultrasonic spray coating approach,...

IdaVac® Vacuum Plates are an innovative solution for flexible surface coatings, providing excellent surface fixation and increasing the precision of the process. These plates we have developed play a critical role in fixing and coating flexible surfaces, especially textiles, membranes, filters, medical material coatings and similar flexible surfaces. Our vacuum plates, which offer solutions suitable for different needs with heated and non-heated models, have a wide range of applications from research and development laboratories to large-scale production lines. In this way, it maximizes production quality by increasing process efficiency in sectors requiring advanced technology.

Technical Specifications:

| MODEL | IdaVac-RT2525 | IdaVac-HT2525 |

| MAX. TEMPERATURE | Non-heated | 200°C |

| SURFACE MATERIAL | Aluminum | |

| DIMENSIONS (MM) | 250x250x30 | |

| CLAMPING AREA (MM) | 230×230 | |

| DIMENSIONS AND CLAMPING AREA (MM) (OPTIONAL) | customized in different sizes | |

| POWER CONSUMPTION | 2.1kW, 220V/50Hz | |

| Certification | CE, ISO 9001:2015 | |

Vacuum plates have a wide range of industrial applications and are used in many sectors. Here are some important industrial applications:

• Electronics and Microelectronics:

Vacuum plates provide surface stabilization in the production of flexible circuit boards and thin film coatings, allowing precise and homogeneous coating.

• Photovoltaic Solar Cells:

In the production of solar cells, vacuum plates provide uniform fixation of flexible surfaces, especially when coating thin-film solar cells (e.g. perovskite and organic solar cells).

• Medical Device Manufacturing:

When coating on flexible medical materials and devices, vacuum plates provide surface stabilization, creating an ideal environment for micro-coatings.

• Biotechnology and Laboratory Applications:

In the production of biosensors and microfluidic devices, vacuum plates are used to hold and coat sensitive materials in the correct position.

• Textile, filtration and membrane applications:

In the production of functional textiles, filtration technology and membrane coatings, vacuum plates are used to fix flexible surfaces and ensure homogeneous coating.

These industrial applications demonstrate that IdaVac® Vacuum Plates offer an ideal solution for processes requiring high precision on flexible and diverse substrates.

Our vacuum plates offer many unique advantages in laboratory and industrial applications. Here are some of these advantages:

• Reliable Stabilization Technology

The high vacuum power prevents surfaces from shifting or moving during the coating process, a critical advantage, especially when coating flexible materials. This ensures that every area of the coating is of equal quality.

• Homogeneous Heating (Heated Models):

Heated vacuum plates provide a homogeneous heat distribution on the surface. This homogeneous heating makes it possible to treat each area of the coating at the same temperature, resulting in more consistent results. It improves coating quality and process reliability, especially on sensitive surfaces.

• Flexible and Modular Design:

Available in different sizes and temperatures, our vacuum plates can be used in both small-scale laboratory research and large industrial coating projects. They can also be customized according to your needs, making it possible to adapt to different application areas.

• High Durability:

It offers long-lasting use with premium quality aluminum. This allows the product to maintain its performance even in corrosive environments, keeping maintenance and replacement costs to a minimum.

• Fast and Precise Heating:

In heated models, the rate of temperature increase is programmable, allowing the desired temperature to be reached quickly and precisely. This feature provides better control while optimizing process times.

• Easy Operation and Maintenance:

Our vacuum plates have an extremely simple and user-friendly structure. Thanks to their quick installation and easy maintenance features, users can perform highly efficient operations without wasting time.

• Wide Application Area:

It can be used in a wide range of applications, from laboratories to large-scale production facilities. This versatility makes the products suitable for any flexible surface coating process.

These advantages are the main reasons why our vacuum plates are preferred in laboratory and industrial applications. These superior features we offer our customers significantly contribute to achieving their business goals by increasing the efficiency and reliability of their processes.

"Since its installation in our lab in Metallurgical and Materials Engineering Department, the UltraSprayer-Starter system has not only facilitated our ongoing research on solar cells and photocatalyst thin films, but also significantly expanded our research capabilities by enabling the coating of metallic materials. Its ease of use in non-vacuum environments, advanced electronic infrastructure, and suitability for large-area deposition have made it an integral part of both undergraduate and academic research activities. The system has found widespread use among our students and academic staff alike, supporting a diverse range of experimental studies."

“In our research group, we have been actively using IDASONIC’s triple syringe pump in our spray coating system, and we are very satisfied with the results. For our work on semiconductor thin films—particularly oxide- and sulfide-based compounds for optoelectronic circuit elements—the pump’s precise and stable flow control provides a significant advantage. Even at very low flow rates, it ensures consistent and reproducible performance. This reliability has improved both the accuracy of our experiments and the overall quality of the thin films we produce. IDASONIC’s syringe pump has become an essential tool for our research activities.”

“In our research group at Çanakkale Onsekiz Mart University, we are using IDASONIC’s NanoWeaver® Pro electrospinning system for our studies on advanced wound dressings, particularly targeting diabetic wound healing applications. The system’s high precision, stability, and versatility in nanofiber production allow us to design and fabricate functional wound dressings with controlled morphology and tailored properties. This capability significantly enhances the quality and reproducibility of our experimental results. IDASONIC’s NanoWeaver® Pro has become a key technology enabling us to advance our research on innovative solutions for diabetic wound treatment.”

“At the Department of Metallurgical and Materials Engineering, we are using IDASONIC’s UltraSprayer® Pro ultrasonic spray coating system for our research on transparent conductive oxide (TCO) thin films, particularly aluminum-doped zinc oxide (AZO). The system provides excellent control over film thickness, uniformity, and reproducibility, which are critical parameters in our work. With UltraSprayer® Pro, we have been able to produce high-quality AZO coatings with improved optical and electrical properties, directly supporting our research on next-generation functional materials. The device has proven to be a reliable and indispensable part of our laboratory.”

With the introduction of the Electrospinning System into our laboratory, we immediately noticed a positive shift in our research workflow. Its compact structure and intuitive controls allowed our graduate students to start experiments quickly without the need for extensive training. The device enabled us to fabricate uniform and reproducible nanofiber structures, which had been difficult to achieve with traditional methods. For research groups engaged in nanomaterials, biomedical applications, or advanced composites, this system stands out as a practical educational platform and an innovative tool that enhances both teaching and research. In addition, the responsive technical support and service provided gave us extra confidence, ensuring that we could focus on our experiments without interruptions.

“At COBILTUM, we have been using the NanoWeaver® Pro system in our studies on smart windows, wound dressings, drug delivery systems, and various nanofiber-based coatings. The system offers reliable performance and flexibility, which helps us to work on both materials science and biomedical applications. Its capability to produce uniform nanofibers with controlled properties has made it a practical tool for our research group, supporting different projects in a consistent way.”

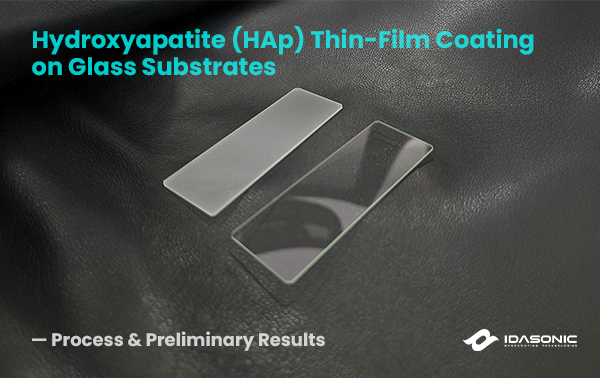

We are excited to share new progress from our biomaterials surface engineering studies. Using a controlled ultrasonic spray coating approach,...

We are excited to share new progress from our biomaterials surface engineering studies. Using a controlled ultrasonic spray coating approach,...

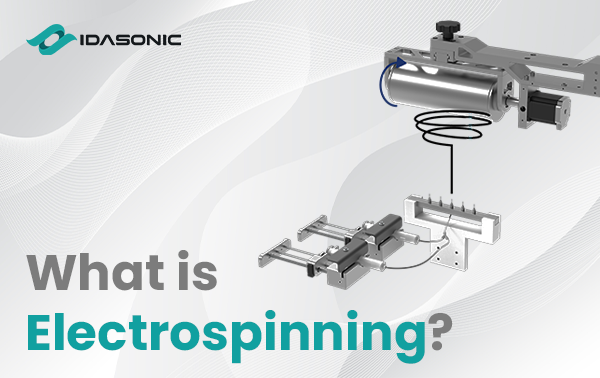

Electrospinning is at the core of next-generation material science. With the ability to produce uniform, functional nanofibers, it is revolutionizing...

They provide exceptional surface fixation using vacuum stabilization, ensuring flexible materials—such as textiles, membranes, filters, and medical substrates—remain perfectly in place during coating processes. This enhances precision and coating quality

Yes. In addition to non-heated versions, IdaVac® offers heated models that deliver uniform surface heating up to 200 °C. This ensures consistent coating results, even on thermally sensitive substrates.

Standard models (e.g., IdaVac-RT2525 and IdaVac-HT2525) feature an aluminum surface, compact dimensions (250 × 250 × 30 mm), and a clamping area of 230 × 230 mm. Custom sizing is also available to suit a variety of application scales.

They are widely applied across sectors including electronics/microelectronics (for flexible circuit coating), solar cell manufacturing (thin-film perovskite and organic solar cells), medical device production, biotechnology (biosensors, microfluidics), textiles, and filtration.

For company news, product updates and releases, subscribe to our newsletter.

© 2016 IDASONIC: Ultrasonic Spray Coating & Electrospinning Systems

Privacy Policy – Terms and Conditions – Cookie Declaration