Our UltraSprayer® devices are meticulously designed to meet the precise and efficient coating requirements in thin film solar cell production processes. This technology offers a wide range of applications, from laboratory-scale research to industrial-level manufacturing, providing several advantages:

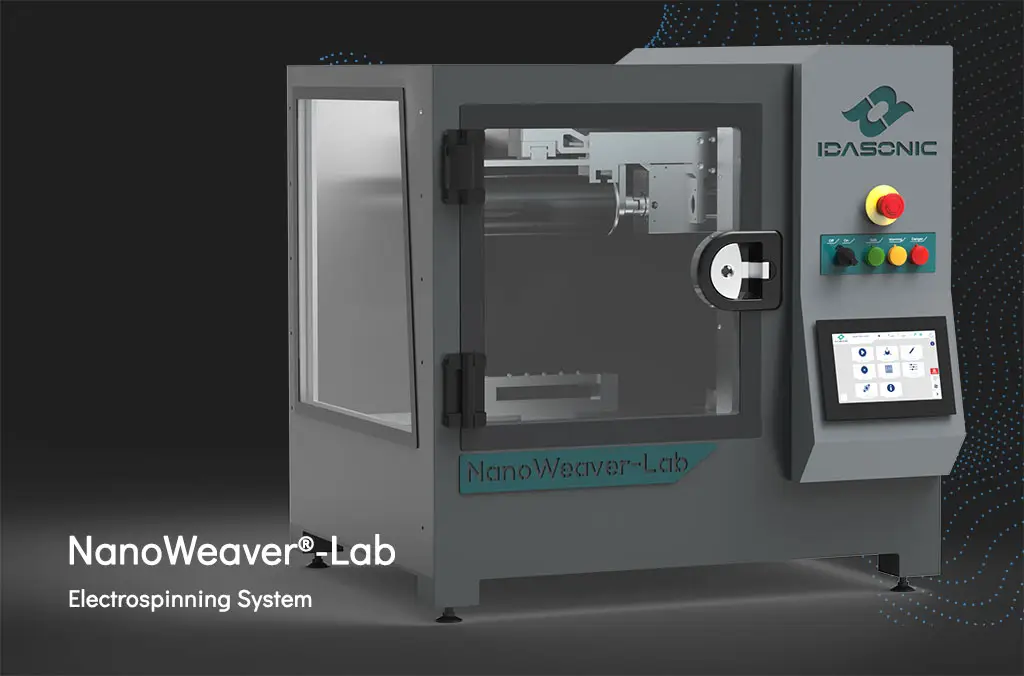

Our NanoWeaver® devices offer perfect solutions for various applications in solar cells. Designed to meet the needs of our customers, ranging from laboratory scale to industrial scale, they provide production capacity and versatility.

Our NanoWeaver® Electrospinning Systems offer ideal solutions to increase the efficiency of solar cells and expand their application areas. We offer flexibility and quality to meet all kinds of needs. Feel free to reach out to us for more information!

At IDASONIC, we offer prompt, effective, and expert support. Whether you need technical guidance or wish to explore customized solutions for your specific requirements, feel free to reach out to us.

At IDASONIC, we offer prompt, effective, and expert support. Whether you need technical guidance or wish to explore customized solutions for your specific requirements, feel free to reach out to us.

For company news, product updates and releases, subscribe to our newsletter.

© 2016 IDASONIC Nanocoating Sysytems and Technologies

Privacy Policy – Terms and Conditions – Cookie Declaration